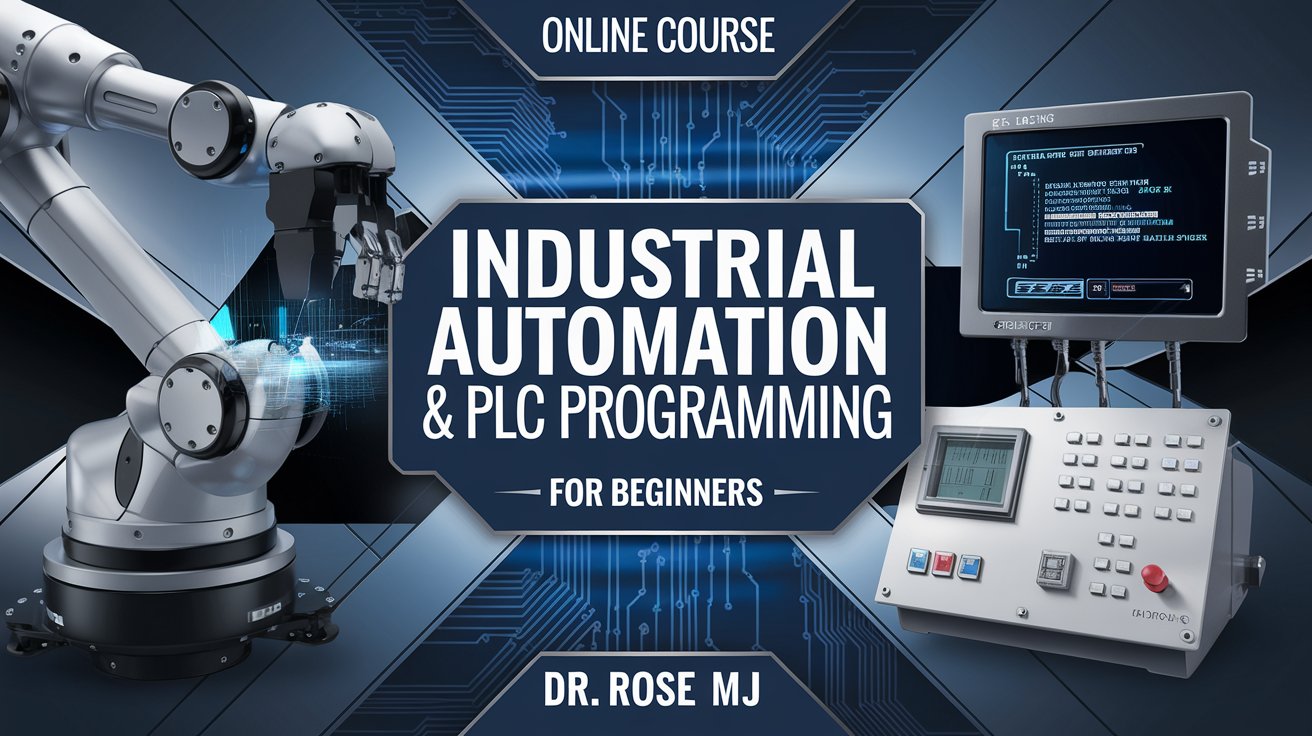

INDUSTRIAL AUTOMATION & PLC PROGRAMMING FOR BEGINNERS

in Higher EducationAbout this course

Industrial Automation & PLC Programming for Beginners

🔹 Master the fundamentals of Industrial Automation & PLCs in a simple and practical way!

🚀 Who is this course for?

✅ Manufacturing & Mechanical Engineering Students

✅ Factory Technicians & Operators looking to upskill

✅ Junior Engineers & Fresh Graduates entering automation industries

✅ Entrepreneurs & SMEs exploring automation for their business

📚 What You’ll Learn:

✔ Basics of Industrial Automation & Control Systems

✔ How to use Sensors, Actuators & Electrical Components

✔ Introduction to PLCs & Ladder Logic Programming

✔ Hands-on PLC Programming (Timers, Counters, Conveyor Systems)

✔ Trends in Industrial Robotics & Industry 4.0

🎓 What’s Included?

✅ Slide Presentations – Clear, structured lessons

✅ Interactive Quizzes – Reinforce key concepts

✅ Hands-on Demos – PLC programming & simulations

✅ Downloadable Resources – Cheat sheets, sample programs

📌 Why Take This Course?

💡 Learn automation in a simple & practical way

⚡ Gain real-world skills for your career in manufacturing

🎯 Taught by an experienced lecturer in Mechanical & Manufacturing Engineering

💥 Get started today and level up your automation skills!

Comments (0)

What is Industrial Automation?

Industrial automation refers to the use of control systems, such as computers, programmable logic controllers (PLCs), and robotics, to manage industrial processes with minimal human intervention. It enhances efficiency, precision, and productivity in manufacturing and production industries.

Importance of Industrial Automation

Increased Productivity – Automation allows for 24/7 operation, reducing downtime and improving efficiency.

Higher Precision & Consistency – Machines perform tasks with greater accuracy and uniformity, reducing human errors.

Cost Reduction – Automation reduces labor costs and minimizes material wastage.

Improved Safety – Replacing human labor in hazardous environments decreases workplace injuries.

Better Quality Control – Automated systems provide real-time monitoring, reducing defects and improving product quality.

Scalability – Industries can quickly scale up production without significant changes in labor.